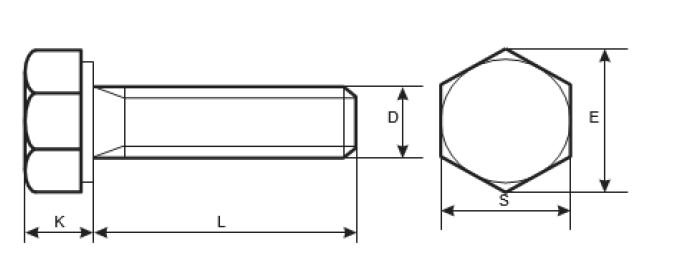

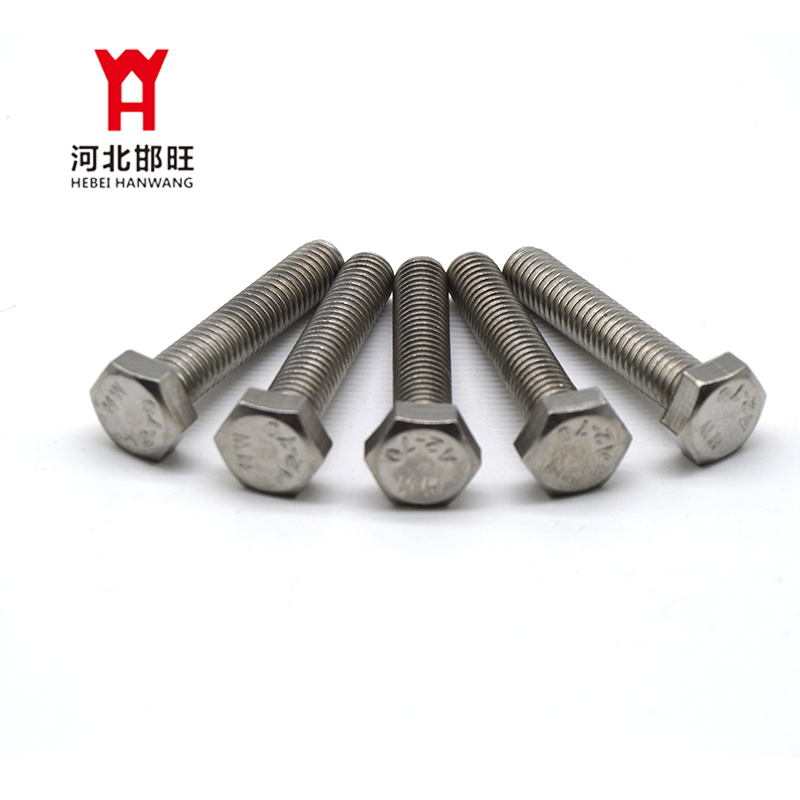

Metric DIN 933 Hexagon Head Cap Screws / Bolts Full Thread

Heibei Hanwang is a market validated Stainless steel Hexagon Bolt Manufacturer based in China, catering to the Industrial Hex Bolt demands of our clients across many industries. We’ve acquired a reputation of being the one of most trusted Stainless steel Hexagon Bolt Suppliers due to our honesty and commitment to our clients.

We fabricate a wide variety of Stainless steel Hexagon Bolt Types with coarse thread density. We offer the best quality Heavy Duty Hex Bolts that are in compliance with international standards. These Bolts are often made from steel of high strength material like high strength alloy steel,often used in general-purpose applications requiring both corrosion resistance and high strength.

Stainless Steel fasteners application

Stainless steel is the material of choice for external applications and environments where corrosion is a factor. Most of Hebei Hanwang stainless steel fasteners are available in the standard grade of A2 stainless steel to suit the majority of requirements. For applications located in marine environments where salt water corrosion is a concern, many of our stainless fastener are also available in A4 stainless steel.

In addition to this, some stainless fixings are available in specific tensile strengths including A2-50, A2-70, ,A4-50, A4-70.

for further information. please contact Hebei Hanwang sales apartment.

Quality Control of Heibei Hanwang Fasteners

Hanwang Fasteners operate a fully controlled quality system maintaining traceability of products from their initial source of supply, into stock, directly through to dispatch to the customer. For that Hebei Hanwang Fasteners established a fully functioning quality control lab and a active quality control office with quality-enthusiasm crew members.

Heibei Hanwang Fasteners Testing Facility

To check that the products we supply conform to the relevant standards and specific requirements of customers, Heibei Hanwang Fasteners operate specialist inspection equipment such as:

- Tensile Machine for pulling kinds of Bolts / Bolts

- Hardness Machine (portable and static)

- Spectrum detection and metallography detection equipment

- Suitability Test Machine for assembly testing

- Both Rockwell hardness and Brinell Testing Machine

- Thread Gauges for bolts and Bolts

- Plating Thickness Tester

For details please contact us for more products specs.

| Dimensions | Millimeters (mm) |

| Material | 304B(AISI/ASTM) |

| Grade | A2-70/A2-50/A4-50/A4-70 |

| Thread | Full thread/partial thread |

| Finish | Black /Zinc Plated/Self color |

| Size range | M3-M26 |

| Packing options | Bag and pallet/Boxed and pallet |

|

Dimensions of Metric DIN 933 Hexagon Head Cap Screws / Bolts Full Thread |

||||||||||||||||||||||||||||||||||||||||||||

|

Mechanical properties of stainless steel for metric DIN 933 Hexagon Head Cap Screws / Bolts Full Thread

Stainless steels can be divided into three groups of steel – austenitic, ferritic and martensitic. Austenitic steel is by far the most common type (>90% of commercial fasteners). The steel groups and strength classes are designated by a four-digit sequence of letters and numbers (eg A2-70) as shown in the following table. DIN EN ISO 3506 governs screws and Bolts made from stainless steel.

Mechanical properties of stainless steel for metric DIN 933 Hexagon Head Cap Screws / Bolts Full Thread

Stainless steels can be divided into three groups of steel – austenitic, ferritic and martensitic. Austenitic steel is by far the most common type (>90% of commercial fasteners). The steel groups and strength classes are designated by a four-digit sequence of letters and numbers (eg A2-70) as shown in the following table. DIN EN ISO 3506 governs screws and Bolts made from stainless steel.

Stainless steels can be divided into three groups of steel – austenitic, ferritic and martensitic. Austenitic steel is by far the most common type (>90% of commercial fasteners). The steel groups and strength classes are designated by a four-digit sequence of letters and numbers (eg A2-70) as shown in the following table.

|

Mechanical properties of stainless steel for metric DIN 933 Hexagon Head Cap Screws / Bolts Full Thread |

||||||

|

Screws, Bolts and Bolts |

||||||

| Steel group | Steel grade | Strength class | Tensile strength N/mm2 | Tensile strength PSI | Dia range | Bolt Load N/mm2 |

|

Austenitic |

A2 and A4 |

50 |

500 |

70,000 |

<=M39 |

500 |

|

70 |

700 |

100,000 |

<=M20 |

700 |

||

|

80 |

800 |

118,000 |

<=M20 |

800 |

||

| Steel group | Property Strength class | Made From |

Characteristics |

|

|

Austenitic |

50 |

A1, A2 |

Soft; cold worked, turned and soft pressed fasteners | |

|

70 |

A2, A4 |

Cold worked, normal strength formed fasteners | ||

|

90 |

A2, A4 |

Extreme cold worked, high strength, special | ||

Chemical composition of stainless steel metric Hexagon Head Cap Screws / Bolts Full Thread

| 牌号 |

化学成分 chemical composition % |

材料特性 Mechanical properties |

|||||||||

|

TPYE |

C Carbon 碳 |

Si Silicon 硅 |

Mn Manganese 锰 |

P Phosphorus 磷 |

S Sulfur 硫 |

Ni Nickel 镍 |

Cr Chromium 铬 |

Mo Molybdenum 钼 |

Cu Copper 铜 |

Others |

|

|

201 |

0.15 |

1.00 |

5.5-7.5 |

0.06 |

0.030 |

3.50-5.50 |

16.0-18.0 |

—— |

—— |

N≤0.25 Nitrogen氮 |

属节镍钢种,冷加工后有磁性。可代替SUS310使用 |

|

302 |

0.15 |

1.00 |

2.00 |

0.045 |

0.030 |

8.0-10.0 |

17.0-19.0 |

—— |

—— |

在硝酸、大部分有机酸和无机酸、水溶液、硝酸,碱及煤气等介质中具有良好的耐蚀性。冷加工后有高的强度。 |

|

|

304 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

8.0-10.0 |

18.0-20.0 |

—— |

—— |

有良好的耐腐蚀性,被广泛使用。 |

|

|

316 |

0.08 |

1.00 |

2.00 |

0.045 |

0.030 |

10.0-14.0 |

16.0-18.0 |

2.0-3.0 |

——

|

在海水及各种有机酸等介质中,耐腐蚀性更好。为重要的耐腐蚀材料。 |

|

![[Copy] GB /T 10433 – 2002 Cheese Head Studs For Arc Stud Welding](http://cdn.globalso.com/jzhw-fastener/301-300x300.jpg)